With Inflation, Cost is Front & Center

In the current inflationary environment, we’ve all become much more conscious of all of our costs. You’re likely looking for ANY way to keep your costs in control, especially as there is so much uncertainty in the marketplace.

Raw material costs have been fluctuating dramatically in recent months and that’s made estimating job costs very difficult in the short term.

We recently had conversations with 3 of our Customers on projects where there were 3 different opportunities for them to reduce costs on their raw materials.

Every situation is different, but here are three ideas to consider when working to optimize the raw material selection for any of your CNC machined products:

3 Ideas You Can Use – Net Shape Raw Materials:

1. Design Thickness

When designing components, it’s easy to start with a nice round number for the thickness of the part. For example, we see plenty of drawings with parts that are 1” thick. Unfortunately, there are many times when using a “generic” size and that can cause confusion or an increase in the cost associated with the part.

Here is an example of this situation:

One of our Customers asked us to quote a new project. The part was 0.5” thick and was a CNC machined component of reasonable complexity.

Of course, the Customer is quite price-sensitive (especially these days!) and was looking to keep the part “affordable”.

Right away, our Team recommended adjusting the design of the part to 0.470” thick, if possible.

There were two reasons that this suggestion made the most sense:

- It was clear from the use of the part, that the thickness of the part was not important to its designed use. Nothing attached to the part on that thickness and it wasn’t mating with anything else that would make it look strange if it were 0.030” thinner.

- The design had machine-engraving on both sides of the part. Machine engraving is very sensitive to depth which means that the thickness of the part needs to be held very consistently. Raw stock is typically specified to be within 5% of the nominal size. Thus, 0.5” material can vary between 0.475” & 0.525”. For the machine engraving to turn out best, the material should be cut to a specific thickness just prior to the engraving. Setting the thickness of the part at 0.470” would ensure that any industry-standard raw material would allow that the part could be machined prior to engraving.

If the 0.5” size was important to the function of the part, then the raw material would need to be purchased as a larger size (0.625” or 0.75”) so that the part could be machined down to the specific finish size of 0.5”. Ordering raw stock at 0.5” thick, could yield a thickness under the desired 0.5” thickness.

The Result– being able to use 0.5” raw material is a significant cost savings over a thicker raw material.

2. Material Alloy

Another Customer of ours was interested in having us produce a stainless steel part. The part was designed to reference a particular alloy.

Different alloys of material have different properties.

Sometimes, the parts are made with a particular alloy for very specific reasons.

Oftentimes, however, a particular alloy isn’t important, it’s just establishing the type of material needed (i.e. aluminum, steel, stainless steel, etc.).

In the case of our Customer’s request, they really just needed a stainless steel part…..the alloy wasn’t important in this situation.

Finding that out helped them save money because we were able to find a much more cost-effective alloy of stainless steel than was originally listed and it was also more readily available.

3. Net Shape Options

Finally, we just had a conversation with a customer preparing for a new product launch.

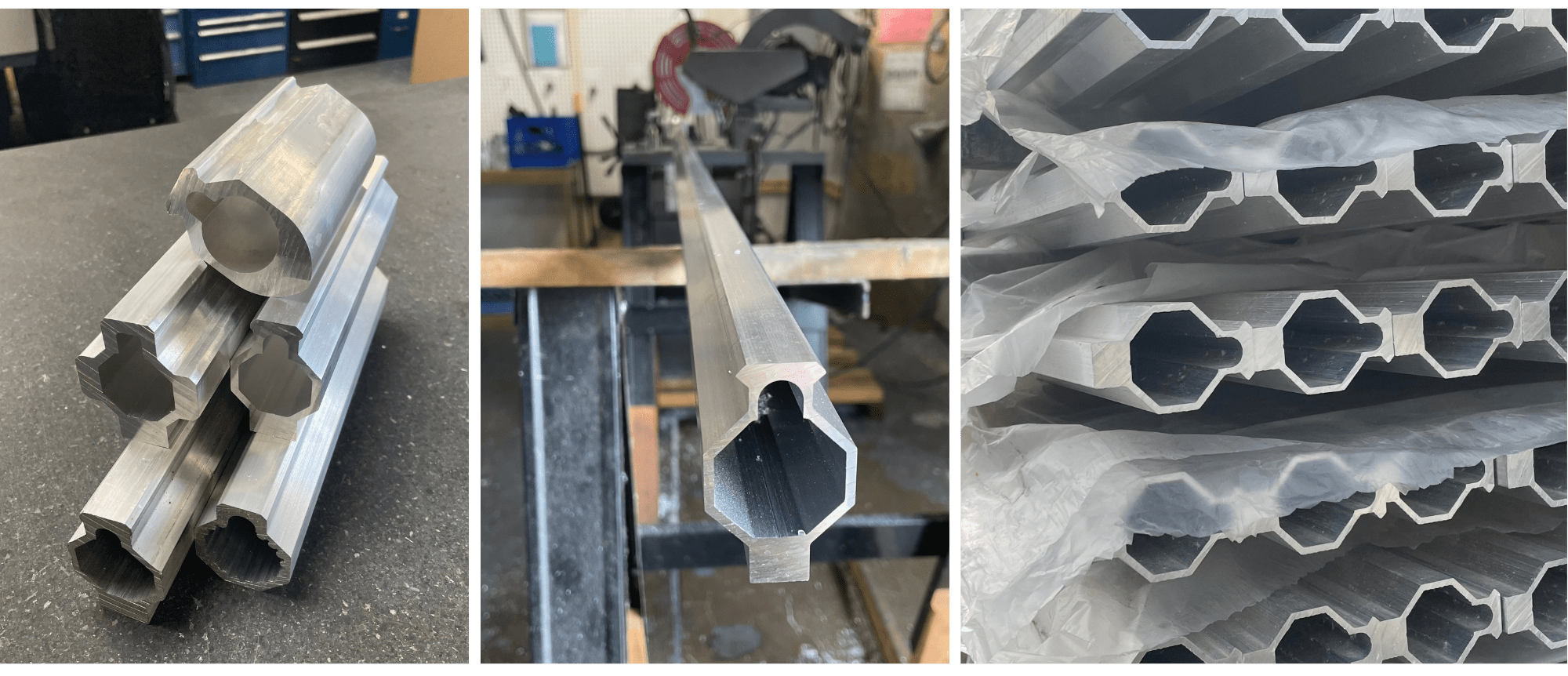

In working to establish higher volume pricing if the roll-out goes well, we discussed the options for using a net shape raw material…..in this case it was an aluminum forging.

Net shape raw materials (castings, forgings, extrusions to name a few!) are sometimes necessary in order to produce the part, but more often, they are just a way to remove cost if there is sufficient volume to support the tooling costs.

- Castings, there are many different types of Castings (Investment Castings, Sand Castings, Die Casting to name a few!) but many different materials can be used. In general, castings are produced when molten material is poured into tooling where it cools to form the part. The cost of Casting tooling can vary dramatically depending on the type of casting, the part size and the raw material needed, but typically starts at least at $10K and goes up from there. One notable limitation of castings is the potential for small air pockets in the finished castings (called porosity) that could cause problems depending on the use of the parts.

- Forgings are similar to Castings, because the tooling helps shape the part. Unlike Castings, Forgings are created by large presses that use impact to form the raw material into the final shape. Imagine a big hammer pounding a piece of raw material into a form just below where the hammer hits.Forgings are typically extremely strong, as the material is compressed into tight geometry, but they cannot typically hold as tight of tolerances as Castings. Tooling for forgings tends to start in the $25K range and go up from there, again depending on the size, geometry and material needed.

- Extrusions are another very common net shape option in aluminum. Extrusions lend themselves to long, thin parts and are similar in concept to a cookie press. A die is produced and molten aluminum is pressed through it so that it squirts out through the die in a particular shape that is cooled as it proceeds down the line. Typically, Extrusions are cut to length or to standard 12-foot lengths as they come off the line. Tooling and a minimum initial batch of material start around $5K and go up from there.

In the case of our Customer, as he projects the potential to run 5,000+ units of his product, using a net shape raw material begins to make sense.

Based on the geometry and use of the part, a forging would be required to provide the strength needed for its intended purpose.

Despite the high upfront tooling cost of the Forging, the resulting production price in production would pay off if the product launch goes well.

This is an example of how using net shape raw materials can reduce product cost as the number of required parts grows.

Final Thoughts

A part design rarely starts with the raw material as the most important aspect. The geometry of the part usually is the primary consideration.

Raw material selection, however, can play a huge role in optimizing the cost of the finished part, and using the 3 ideas above should help.

The above conversations with our Customers are examples of the discussions that we have as we review projects each day.

Our desire to be the Next Best Thing to an In-House Shop for our Customers starts with a thorough project review and a transparent review of the costs associated with producing the parts.

We love helping our Customers optimize their products so they can help their customers solve problems and win. Using the best choices for raw materials helps everyone win.

If you’re interested in having open conversations about your CNC Production Parts, please contact us below and we’ll look forward to speaking with you soon.