We continue our Managing Your Supply Chain Series and our next topic is Manufacturing Difficult Parts & Assemblies.

Some companies are completely vertically integrated, handling all of their manufacturing processes without assistance from outside Vendors. That’s the exception, rather than the rule, however, because most companies are good at a few things and outsource the rest to capable Vendors. As components and assemblies get more complicated, the range of skills required grows dramatically. The complexity can also mean greater opportunity for creativity and ingenuity included in the process to drive improved results.

A vertically integrated organization likely has plenty of “experts” within the organization to provide varieties of ideas when new products are being considered. It’s important that they have a systematic means of soliciting input from across the spectrum of their company to maximize their productive output. Most companies that aren’t fully vertically integrated need to rely on input from outside their Company to get fresh and “expert” ideas to improve productive output.

In our Managing Your Supply Chain Series, we’ve talked quite a bit about engagement between Customers and Vendors. In this installment, we’re sharing 3 factors that could be limiting your opportunity to capture new ideas and to optimize your complicated components and assemblies.

3 Limiting Factors Will Keep You from Optimizing

1. If it’s Difficult to Remain Open to New Ideas and Possibilities

Inertia is always challenging to overcome. The way you currently do things became that way for a reason and making changes isn’t easy. Things that you “know to be true” can limit your ability to adjust your perspective. You’re human, so you routinely make assumptions about how things should be done and those assumptions are hard to shake. There are always alternatives but only if you choose to look for them.

The more complicated the product or assembly, the more different disciplines can be involved and the more alternatives could be possible. Remaining open to possibility, especially as technology is continuously evolving, is very difficult.

Blind spots are called blind spots because you can’t see them. You want to regularly push your own boundaries and methodologies to look for new ways to look at your world. New ideas always seem so obvious, but only after you discover them!

2. If it’s Difficult to Experiment within Your Company’s Systems of Operation

Inertia is always challenging to overcome. The way you currently do things became that way for a reason and making changes isn’t easy. Things that you “know to be true” can limit your ability to adjust your perspective. You’re human, so you routinely make assumptions about how things should be done and those assumptions are hard to shake. There are always alternatives but only if you choose to look for them.

The more complicated the product or assembly, the more different disciplines can be involved and the more alternatives could be possible. Remaining open to possibility, especially as technology is continuously evolving, is very difficult.

Blind spots are called blind spots because you can’t see them. You want to regularly push your own boundaries and methodologies to look for new ways to look at your world. New ideas always seem so obvious, but only after you discover them!

3. If it’s Difficult to Create Open Dialog Outside Your Company

Open dialog is challenging to create in almost any situation. Everyone brings their emotions to conversations, so even if you have a great group of people with diverse perspectives the human dynamics can limit the opportunity. Conversations about ideas rely on who has the power, the social capital, or the loudest voice and that isn’t usually helpful. Generating new ideas, especially for difficult problems, components, or assemblies, is fraught with human tension.

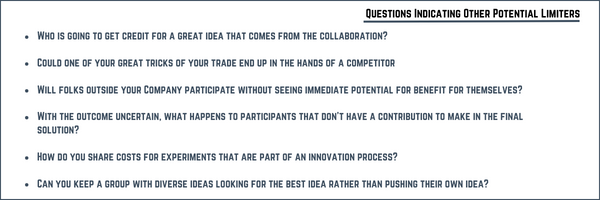

Besides the emotional aspects of getting a group comfortable with open dialog, there are at least a handful of other potential limiters:

These questions are relevant inside your Company, but their weight increases when dealing with people outside your Company. Ideally, you can draw on a variety of perspectives while recognizing that everyone brings their particular “hammer” to the conversation and is looking for their particular type of “nail” within the problem.

It’s rare that a diverse group of outsiders is assembled by an organization to solve difficult problems. It would be nice, but the logistical hurdles and some of the questions listed make it too challenging. Even so, being open to outside collaboration is an important opportunity that can provide transformative solutions to difficult components and assemblies.

There are always alternatives to what you’re doing and staying open to possibilities is important if you want to see them. Getting new ideas outside your Company can expand your opportunities if you’re thoughtful in your approach.

Final Thoughts

If yours is like most manufacturing organizations, you rely on your Supply Chain for more than just components and services. You rely on their expertise. Using their know-how to help optimize your most difficult components and assemblies is an opportunity that can be transformative for your business.

Stay open to new ideas and possibilities. Create an experimental process within your Company for innovative iterations. Organize groups of people with diverse ideas and thought processes so that together they can create transformative ways to solve challenges.

Unfortunately, it’s easy to stick with your current assumptions about how to make your products. Few would say they always want to keep doing things the same way, but most often it’s a struggle to consider new perspectives. Innovation is not easy, but the more complicated the components and assemblies, the more opportunity exists.

In our final installment of our Managing Your Supply Chain for Success Series, we’ll discuss getting meaningful delivery commitments from your Vendors.