CNC Contract Manufacturing Price and Cost

Optimize the Process with Transparent Pricing

The quest for price and cost optimization is relentless in the intricate world of CNC (Computer Numerical Control) contract manufacturing. When projects are complex, the traditional RFQ (Request for Quotation) process (the industry’s primary method for getting bids) shows how limited the practice is. Enter the CNC Pricing Transparency Model, a transformative approach that promises to revolutionize how we think about CNC contract manufacturing price and cost.

The Traditional RFQ Process

The conventional RFQ process in CNC contract manufacturing is straightforward: buyers send component drawings and technical details to multiple suppliers. After a review period, these suppliers return with quotes detailing CNC contract manufacturing price, cost, and expected lead times. This model works efficiently for simpler parts, where the risk to the buyer is minimal if a supplier fails to meet specifications.

However, as the complexity of projects increases, this model’s limitations are highlighted. Complex engineered products require a more detailed evaluation of suppliers to ensure they can deliver quality components while adhering to CNC contract manufacturing price and cost considerations. Complexity necessitates that a supplier’s Engineering and QA Departments match the sophistication of the buyer’s requirements, a task easier said than done.

The CNC Pricing Transparency Model

The CNC Pricing Transparency Model is a paradigm shift that can lead to better results mutually beneficial for both the buyer and the supplier. It emphasizes open dialogue and detailed cost analysis between the technical teams of both the buyer and the supplier. By fostering this collaboration, design and manufacturing parameters can be explored in-depth, ensuring value maximization while keeping a keen eye on CNC contract manufacturing price and cost.

This model is especially crucial for complex projects. The synergy between both parties’ Engineering & QA Teams can lead to significant optimizations that the traditional RFQ process would likely miss.

The Power of Collaboration

The CNC Pricing Transparency Model’s strength lies in its collaborative approach. Instead of operating in silos, the buyer and seller’s technical teams combine their expertise.

This synergy can lead to innovative solutions, better project management, and, most importantly, optimized CNC contract manufacturing price and cost.

Industry Hesitation to Adopt the CNC Pricing Transparency Model

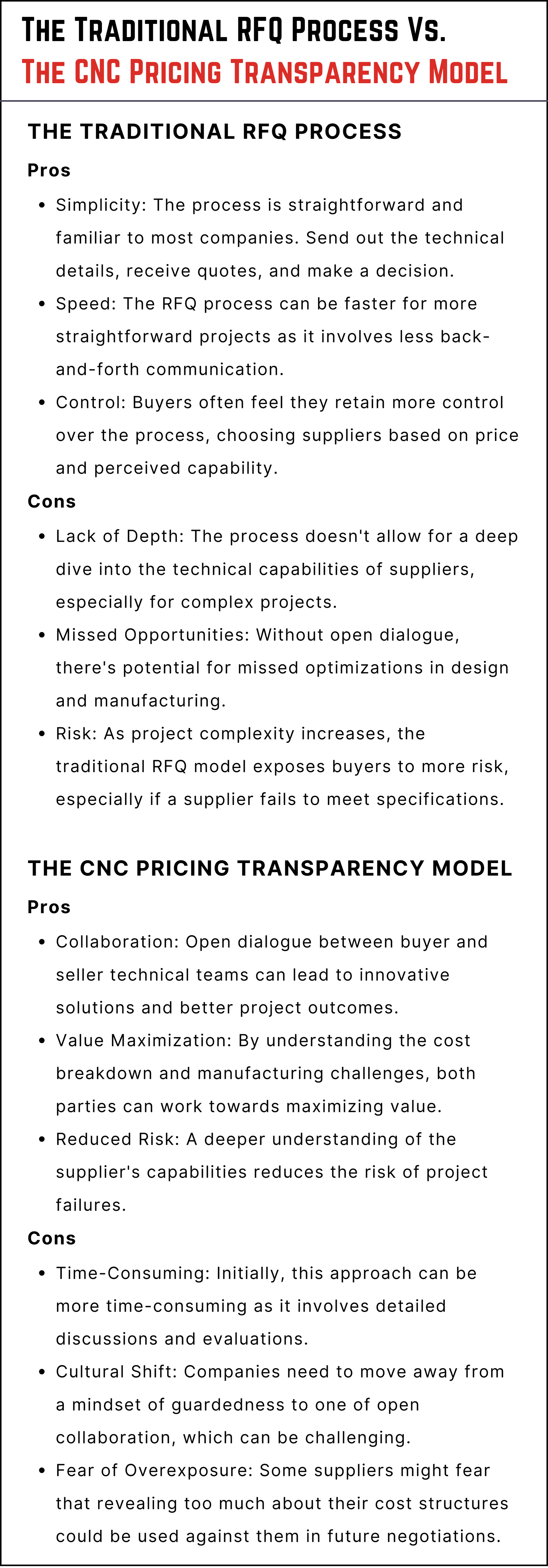

While the CNC Pricing Transparency Model offers many advantages, it’s essential to understand why many companies have been slow to adopt it. The traditional RFQ process, despite its limitations, has been deeply ingrained in the industry’s fabric for years. Let’s delve into the reasons behind this hesitation and weigh the pros and cons of each approach.

Why the Reluctance to Change from the Traditional Model?

Why the Reluctance to Change from the Traditional Model?

Fear and inertia are the primary reasons many companies need to be faster to adopt the CNC Pricing Transparency Model. The manufacturing industry, like many others, is often resistant to change. The traditional RFQ process, despite its flaws, is a known quantity. There’s comfort in familiarity.

Moreover, there are fears for both Buyers and Suppliers. The Supplier’s fear of overexposure is real, worrying about revealing too much. At the same time, buyers are concerned about the initial time investment required for the CNC Pricing Transparency Model and their ability to mobilize their Engineering and QA Teams. However, as the benefits of this new approach become more evident, more companies will likely begin to see its value.

Shifting Paradigms for a Brighter Future

While the traditional RFQ process has served the industry well, it’s time to look forward. The CNC Pricing Transparency Model offers a fresh perspective, one that prioritizes open communication, collaboration, and, above all, value maximization. As projects grow in complexity, this model will undoubtedly become the gold standard for CNC contract manufacturing price and cost optimization.

In conclusion, the CNC Pricing Transparency Model is a new approach and a necessary evolution in CNC contract manufacturing. By emphasizing collaboration and open dialogue, it promises to deliver unparalleled value, ensuring that CNC contract manufacturing price and cost are optimized for today’s and tomorrow’s challenges.

If you’re curious about how adding transparency to your Customer-Vendor interaction can provide peace of mind, reach out to us today. Discover the potential of the CNC Pricing Transparency Model and its benefits for optimizing CNC contract manufacturing price and cost for your complex projects.