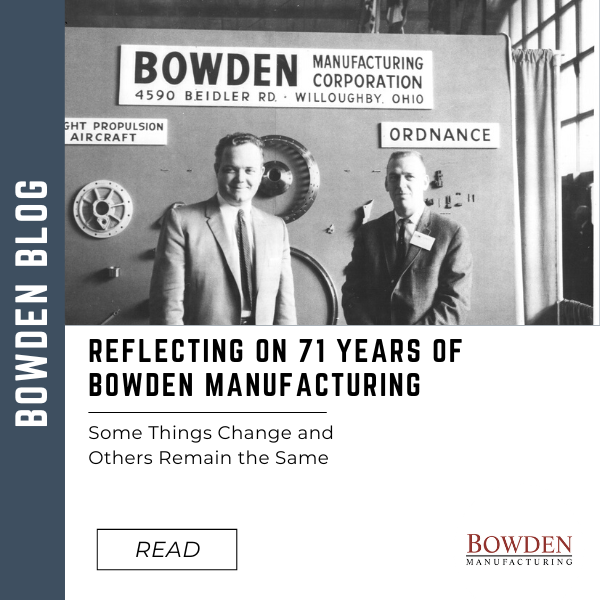

“The more things change, the more they stay the same.” It’s been 71 years since the start of Bowden Manufacturing and keeping up with dramatic adjustments to the way manufacturing gets done is an ever-evolving challenge. We’ve all witnessed the jump from completely manual machines to CNC machining centers and from localized markets to global competition. Especially considering the rapidly advancing Artificial Intelligence and Industry 4.0 technologies, we thought it would be a good time to reflect on the three biggest changes we’ve seen since our founding in 1952. We also thought it would be important to highlight three big aspects of our role in manufacturing that have remained largely the same.

Three Big Changes in Manufacturing Since 1952

1. Digitization

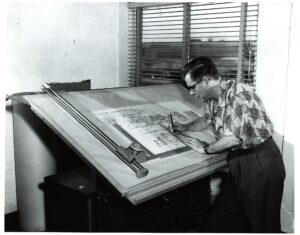

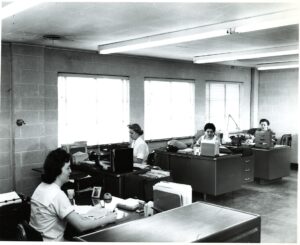

Data in 1952 was analog. Drawings were on paper and created at a drafting desk. Machines were manual and each part was produced by hand. Calculations were manual and controls for machines were analog.

Today, data and drawings are contained in electronic files. Geometry is typically represented in 3D CAD (computer-aided design) models. Software manipulates the data for CAM (computer-aided manufacturing) processes that often include CNC (computer numerical control) machines of various types to produce products. For the most part, paper drawings remain merely to meet human communication preferences, rather than as a primary means of translating data.

2. Global Supply Chains

In 1952, most manufacturing took place within a single geographic area. Even as information became more widespread across the world, the logistics required to make international connections were limited and expensive.

Today, manufacturing operates on a global scale, with interconnected supply chains and international trade networks. Local manufacturing still has a competitive advantage in some cases, but the worldwide availability of products and manufacturing services has dramatically altered the landscape. Nationalistic preferences and the regulations set up by governments have played a significant role in determining market cost and acceptance as products can now be affordably shipped around the world.

3. Automation & Industry 4.0

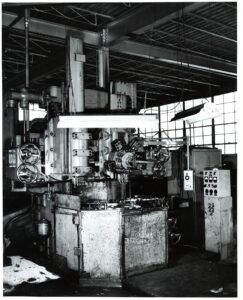

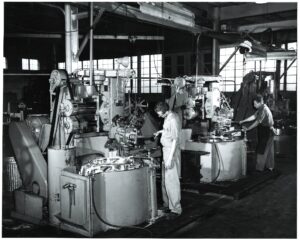

Automated processes and tools were still in their infancy in 1952. The drive to increase factory productivity was growing but mainly was dependent on human workers and their direct efforts.

Today, manufacturing relies heavily on the use of technology for productivity. The tools for automating processes to reduce cost and increase productivity are widespread. From increasingly automated equipment to extremely sensitive monitoring and measuring processes, the advance of Industry 4.0 is designed to help products and information flow smoothly from shop floors to wherever needed.

Three Big Aspects of Manufacturing That Have Remained Largely the Same Since 1952

1. Customer Service

While the nature of manufacturing Customers may have changed since 1952, their desire for a high degree of Customer Service hasn’t changed. People are still at the heart of the Customer-Supplier interaction. Modern tools and technology have enhanced communication and logistics, but aligning those systems with Customer preferences remains extremely important. The expansion of the global marketplace has expanded the competitive landscape in manufacturing, yet the importance of understanding and solving Customer problems is still paramount.

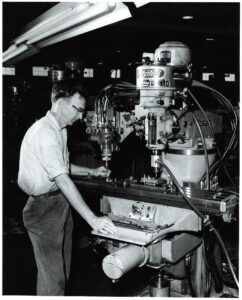

2. Talent & Teammates

In 1952, most manufacturing was performed manually by skilled technicians. Training through apprenticeships was a primary vehicle for workers to gain skills and experience. As automation and technology have streamlined manufacturing processes, the workers’ roles have evolved over time. Yet the ingenuity and skill set of the talent remains a critical component to success. Ultimately, the ways the machinery generates productive output still originate with the human mind. Building a successful Team in any manufacturing endeavor will depend on the Teammates, their skills, and their ability to maximize the productive output of the resources at their disposal.

3. Innovation & Ideas

The significant changes that we’ve identified between 1952 and today are the results of innovation and ideas as the industry has looked for improvements in just about every imaginable area. From automation and digitization to advanced materials and sustainable manufacturing practices, the opportunity for an improved future lies in the ability to solve new problems and generate new ideas. Manufacturing seeks to meet the needs of a world that is growing in complexity even as global markets have become more interconnected. The ability of companies to solve important problems for their Customers through new ideas and innovations remains a primary opportunity for competitive advantage.

Final Thoughts

We’re pleased to celebrate 71 years of Bowden Manufacturing and look forward with eager anticipation to number 72. We intend to continue striving to be the next-best thing to an in-house shop for our Customers, keeping their needs and interests paramount in all we do. Through our Manufacturing Next Gen Program, we seek to grow the next generation of manufacturing professionals. Today we’ve got the best and brightest Team we’ve ever had. Harnessing the creativity of our Team to use technology tools coupled with the freedom to experiment with innovative ideas and try new things will drive us into a bright future. We’re excited by the prospect of American manufacturing working together to solve important problems while optimizing production methods to remain competitive in a global economy.

Congratulations to the entire Bowden Manufacturing organization and all the Customers, Suppliers, and Teammates that have been part of our journey these past 71 years. It’s been an exciting ride that we expect will continue long into the future!